- KRIGER™ GN-10

- KRIGER™ ECO

- KRIGER™ HYBRID

- KRIGER GP

- KRIGER™ SW

- KRIGER™ NS

- KRIGER™ FM

- KRIGER™ GENERATOR

- (PL) SUSZENIA ZBOŻA

Industrial fire tube two-way gas boiler with a burner with a capacity of 10 MW.

Gas boilers of the GN series can be used for heating residential and industrial premises, hot water supply systems, wood drying chambers equipped with a continuous heating water system with natural or forced circulation, as well as other technological purposes.

| Name of the parameter or size | Value of the parameter or size |

|---|---|

| Model range | KRIGER™ GN-10 |

| Nominal heating capacity, kW | 10000 |

| Range of regulation of boiler heat output,% | 30-100 |

| Coefficient of performance, %, min | 90 |

| Maximum heat carrier temperature at the boiler outlet, °С | 115 |

| Working fluid pressure, MPa, max | 0,40; 0,60; 0,80; 1 |

| Flue gas temperature, °С, min | 160 |

| Sound level, dB, max | 90 |

| Dimensions | |

|---|---|

| Length | 7612 |

| Width | 2986 |

| Height | 3406 |

The model series of ECO series electric hot water boilers are made up of boilers with the mechanized feed of particulate and solid fuel and manual feeding of solid fuel.

ECO boilers can be used for heating domestic and industrial premises, hot water supply systems, drying chambers for wood, equipped with a continuous hot water heating system with natural or forced circulation, as well as other technological applications. These models burn fuels on a stationary grate grid.

| Name of the parameter | Value of the parameter |

|---|---|

| Rated thermal power, kW | 300 – 820 |

| Control range for boiler thermal power, % | 30-100 |

| Efficiency factor, %, min | 85 |

| Exit gas temperature, °С | 160 |

| Operating water pressure, bar | 3-6 |

| Sound level, dB, max | 80 |

| Term of the continuous boiler house operation min, h/year | 8000 |

| Operational service life (years) | 20 |

| Mains voltage | 380 V; 50 Hz |

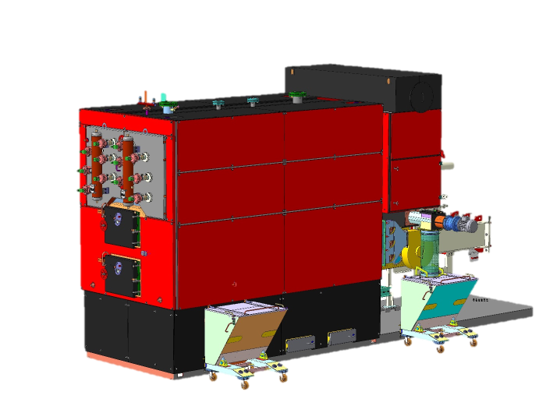

Boilers of the Hybrid line with mechanized burning of bulk fuel on the retort with lower fuel supply. Fuel from the fuel supply hopper of 1.3 m3 is fed to the retort with a screw conveyor and distributed over the grate bars where combustion takes place. To achieve the correct ratio of costs, the supply of primary and secondary air is regulated separately.

The boiler is made of thick-sheet steel, the firebox is lined with refractory brick, insulated with basalt insulation and faced with sheet metal with a polymeric coating.

| Name of the parameter | Value of the parameter |

|---|---|

| Rated thermal power, kW | 300-3500 |

| Control range for boiler thermal power, % | 30-100 |

| Efficiency factor, %, min | 85 |

| Exit gas temperature, °С | 160 |

| Operating water pressure, bar | 3-6 |

| Sound level, dB, max | 80 |

| Term of the continuous boiler house operation min, h/year | 8000 |

| Operational service life (years) | 20 |

| Mains voltage | 380 V; 50 Hz |

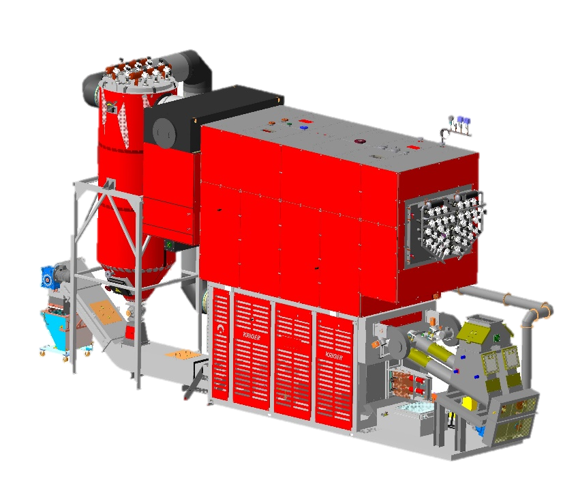

High-tech boiler water-heating plants of the GP series are suitable to work in an automatic mode with minimal human intervention. Created based on the cutting-edge advances and proven technologies for burning solid fuel, boilers with moving grate bars are considered to be the most effective examples of world boiler-houses.

Boilers manufactured by Kriger have many features making them ideal for combustion of various fuel types with a humidity of up to 55 % and at the same time comply with current European standards and norms for the flue gases emission into the environment.

| Name of the parameter | Value of the parameter |

|---|---|

| Rated thermal power, kW | 300 - 10000 |

| Control range for boiler thermal power, % | 30-100 |

| Efficiency factor, %, min | 88 |

| Exit gas temperature, °С | 160 |

| Operating water pressure, bar | 3-10 |

| Sound level, dB, max | 80 |

| Term of the continuous boiler house operation min, h/year | 8000 |

| Operational service life (years) | 20 |

| Mains voltage | 380 V; 50 Hz |

Boilers of SW model are heating devices using water as a heat carrier typically at a temperature of 160 °C and operating pressure of up to 16 bar used in process chains, power plants or heating systems.

Using superheated water also allows to generate electricity with O.R.C turbines, and, due to modern technological solutions and high-quality materials, the boiler has the one of the best energy efficiency indicator in the EU market.

| Name of the parameter | Value of the parameter |

|---|---|

| Rated thermal power, kW | 2000 – 10000 |

| Control range for boiler thermal power, % | 30-100 |

| Efficiency factor, %, min | 88 |

| Exit gas temperature, °С | 115-200 |

| Operating water pressure, bar | 10-30 |

| Sound level, dB, max | 80 |

| Term of the continuous boiler house operation min, h/year | 8000 |

| Operational service life (years) | 20 |

| Mains voltage | 380 V; 50 Hz |

The main purpose of Kriger’s steam boilers is to produce saturated steam, which is used for technological needs of industrial enterprises, as well as in heating, ventilation and hot water supply systems.

The use of well-proven biomass burning technology on a rolling brush grid, combined with a three-way fireplace and modern design, vest Kriger steam boilers with the best technical characteristics and performance. Steam boilers of the Kriger company are distinguished by high efficiency, guaranteed environmental friendliness and maximum reliability.

| Name of the parameter | Value of the parameter |

|---|---|

| Rated thermal power, tp/h | 1,6 - 10 |

| Control range for boiler thermal power, % | 30-100 |

| Efficiency factor, %, min | 87 |

| Steam temperature, °С | 198 |

| Working pressure of steam, bar | 14 |

| Exit gas temperature, °С | 160 |

| Sound level, dB, max | 80 |

| Term of the continuous boiler house operation min, h/year | 8000 |

| Operational service life (years) | 20 |

| Mains voltage | 380 V; 50 Hz |

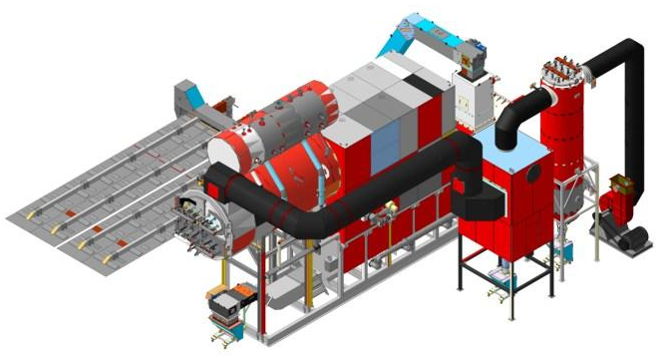

Boiler for the steam production with parameters 39-440 Fire Master series is a unique development of Kriger.

Using advanced engineering achievements in the field of boiler construction, coupled with many years of experience, we received a boiler that is ideal for different types of power plants. Krieger uses exceptional quality materials to provide installation work at nominal capacities for decades.

Together with this boiler, we offer many ready-made solutions for the production of electricity alone or in combination with heating and DHW.

| Name of the parameter | Value of the parameter |

|---|---|

| Rated thermal power, tp/h | 1,6 - 20 |

| Control range for boiler thermal power, % | 30-100 |

| Efficiency factor, %, min | 87 |

| Steam temperature, °С | 440 |

| Working pressure of steam, bar | 39 |

| Exit gas temperature, °С | 160 |

| Sound level, dB, max | 80 |

| Term of the continuous boiler house operation min, h/year | 8000 |

| Operational service life (years) | 20 |

| Mains voltage | 380 V; 50 Hz |

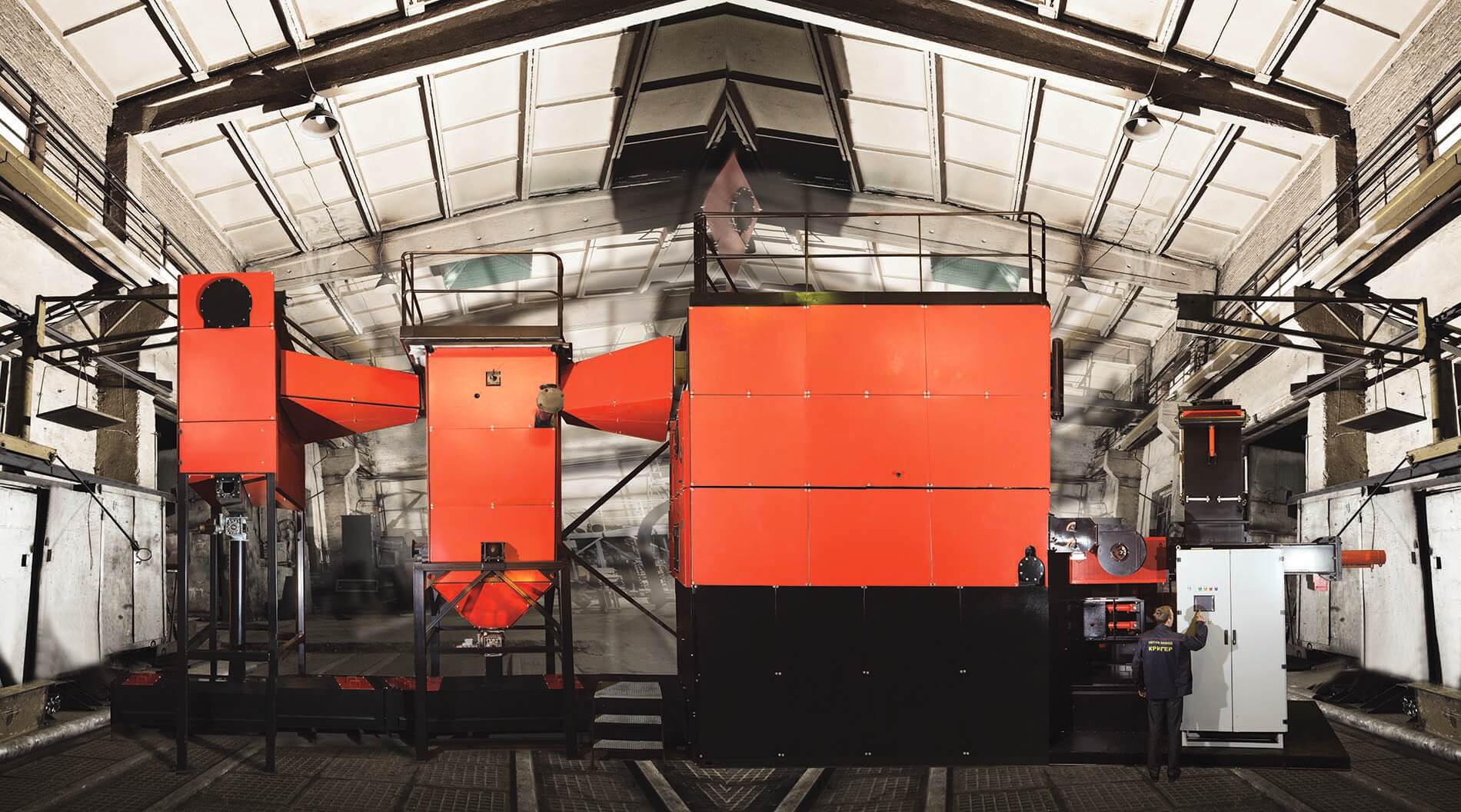

Heat generator of the TGM model is designed for the production of hot air using thermal energy transfer during biofuels combustion.

The generator is used to supply hot air for drying plants at agricultural enterprises when switching them to alternative, cheaper fuels.

The advantage of the generators of this model implies that their application allows obtaining environmentally friendly agricultural products, as the products of fuel combustion do not contact and are fed into the drying installations by air.

Moreover, the heat generator of the TGM model is capable of working with a very wide range of fuels and is very unpretentious to fuel quality.

| Name of the parameter | Value of the parameter |

|---|---|

| Rated thermal power, kW | 300 - 10000 |

| Control range for boiler thermal power, % | 30-100 |

| Efficiency factor, %, min | 92±2 |

| Maximum air temperature at boiler outlet, °С | 90-160 |

| Exit gas temperature, °С | 180 |

| Sound level, dB, max | 80 |

| Term of the continuous boiler house operation min, h/year | 8000 |

| Operational service life (years) | 20 |

| Thermal insulation of the furnace provides a max surface temperature, ° C | 40 |

| Mains voltage | 380 V; 50 Hz |

| (PL) Znamionowa moc cieplna, kW | (PL) 300 - 10000 |

|---|---|

| (PL) Zakres regulacji mocy cieplnej kotła, % | (PL) 30-100 |